> Scope of Application

S11-M-30-2500/10(20)kV type fully sealed oil-immersed transformer is suitable for AC 50Hz, rated working voltage 10kV, 20kV and below power system, as a distribution transformer for petroleum, metallurgy, chemical, textile, light industry and other enterprises and dusty places.

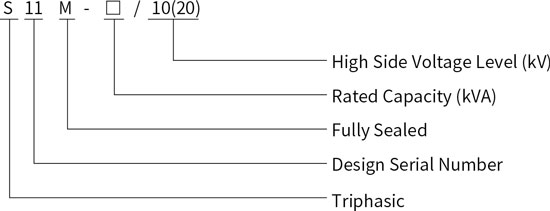

> Model Meaning

> Working Conditions

◇ Installation height: altitude not more than 1000m;

◇ Ambient temperature: -40°C ~+40°C

> Structural Features

◇ Iron core

The iron core is made of cold-rolled silicon steel sheet with high magnetic permeability grain orientation. The iron core is a core iron core, a fully miter seam stacked iron core, and its iron core column is a circular section of multi-step steps, and the yoke and iron core are equal sections.

◇ Winding

The winding adopts corrugated oil channel, non-impregnated paint process, and tightening belt lashing; The windings are all concentric coils: the high-voltage windings have taps corresponding to the tap voltage requirements, which are led to the tap changer, the switch is installed on the box cover, and the voltage transfer of 10kV and 20kV can be realized after the power supply needs to be cut off, and the tap voltage can be converted.

◇ Safety protection device

The 30~2000kVA transformer is equipped with a pressure relief valve;

Gas relays with alarm and trip terminals can be installed according to user needs;

◇ Oil temperature measurement device

The transformers are equipped with a glass thermometer header, which is set at the top of the oil tank and extends 120±10mm into the oil;

The 1000~2000kVA transformer is equipped with an outdoor signal thermometer;

◇ Transformer tank

The transformer tank is composed of corrugated walls, and the surface is sprayed with dust and the paint film is firm. The corrugated heat sink not only has a cooling function, but also has a "breathing" function, and the elasticity of the corrugated heat sink can compensate for the change in transformer oil volume caused by temperature rises and falls. Therefore, the fully sealed transformer has no oil storage cabinet, which reduces the overall height of the transformer;

The transformer adopts a vacuum oil injection process when encapsulating, which completely removes moisture in the transformer, and the transformer oil does not contact with air. Effectively prevent oxygen and moisture from invading the transformer and causing the transformer insulation performance to decline and the possibility of transformer oil aging, so oil sample tests are not carried out regularly;

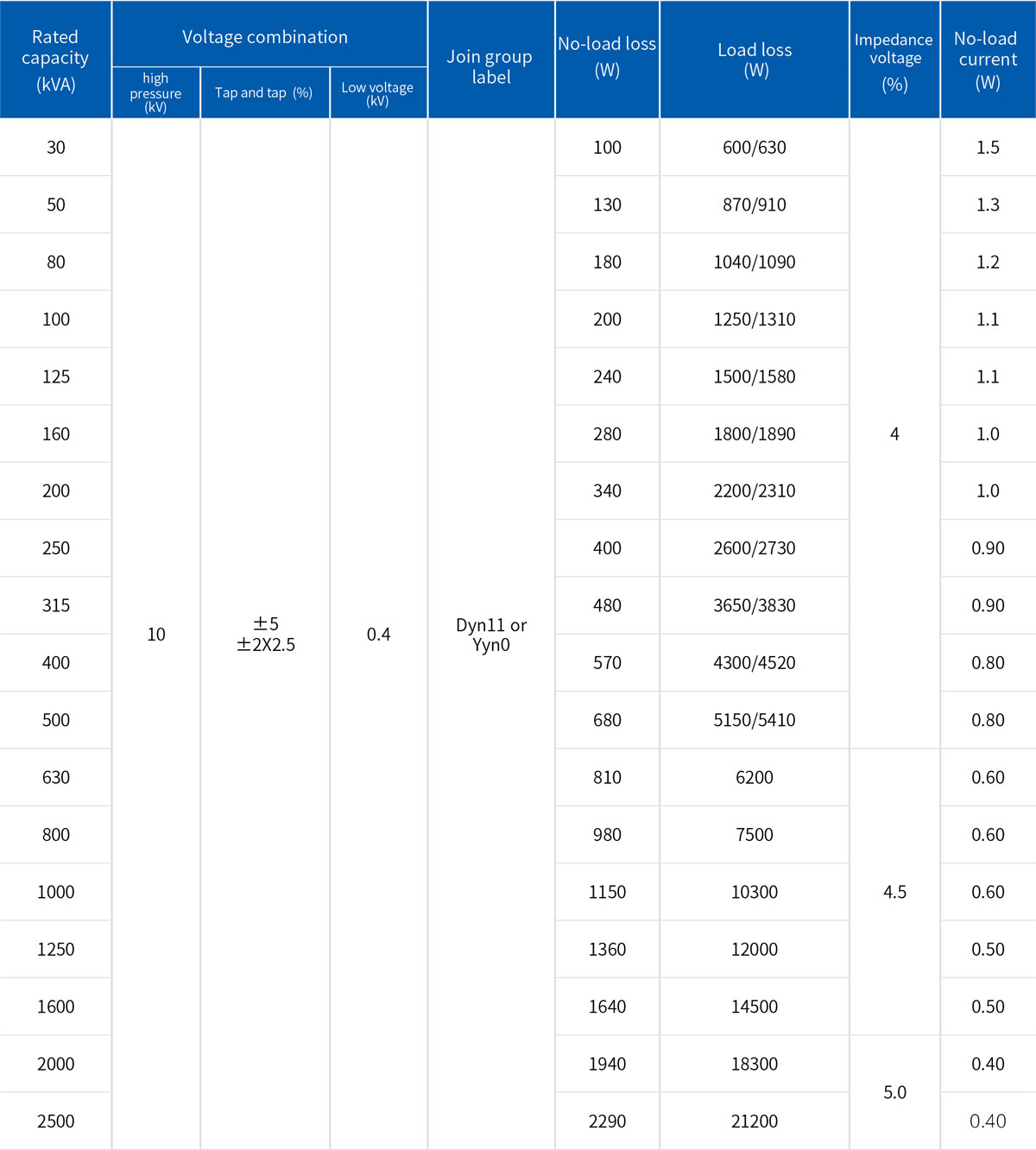

> Main Technical Parameters

Note:

1. The load loss value below the slash in the table applies to the products of the Dyn11 connection group.

2. The weight and external dimension data in the table are for reference only, and are subject to change without notice.

3. Please consult our company for technical parameters, dimensions and weight data of transformers with larger capacity.

China

China English

English Pусский

Pусский